Sensorless zero-speed torque

for PMSM drives

Start heavy loads without a rotor position sensor

Less wiring, fewer parts, fewer failure points

Pumps and starter-generator start events

Without a position sensor, many sensorless PMSM drives struggle to deliver high torque exactly at standstill — the moment your pump or starter needs it most.

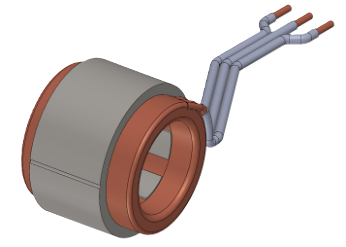

Our rotor magnetic geometry creates different inductance in different directions — a "fingerprint" of rotor angle.

A small HF test signal is injected into the main windings (for a short time) during start.

Firmware reads the saliency response to estimate rotor angle → FOC can create torque immediately.

| Stator outer diameter: | 60 mm |

| Torque range (typical): | 3–5 N·m |

| Active magnetic length: | 31–53 mm (by magnet stack) |

| Status: | In production |

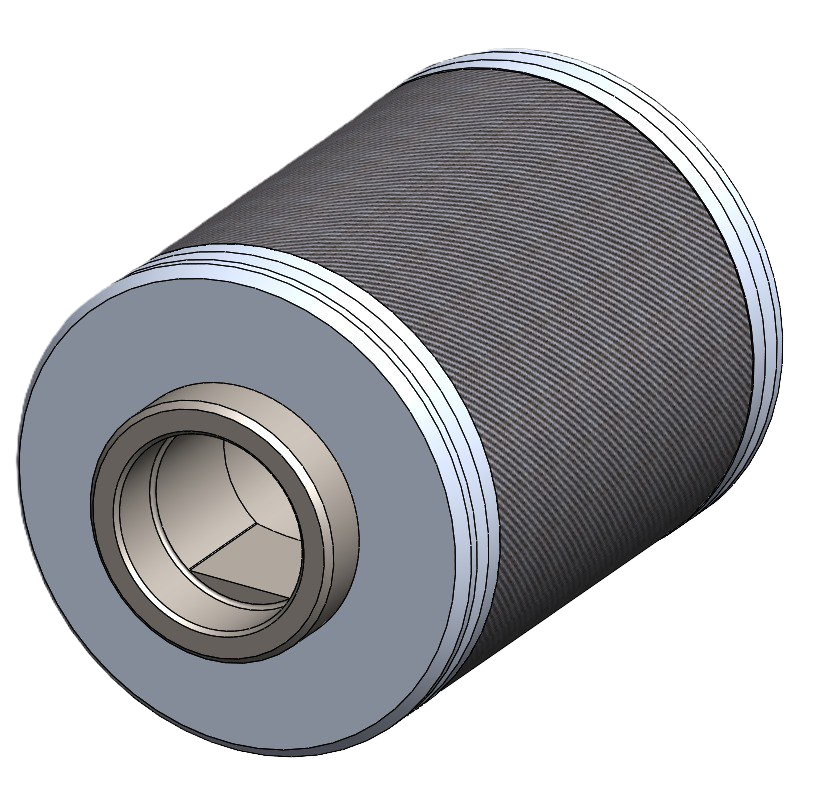

| Stator outer diameter: | 42 mm |

| Torque range (typical): | 0.5 N·m |

| Active magnetic length: | 22 mm (by magnet stack) |

| Status: | Prototype build |

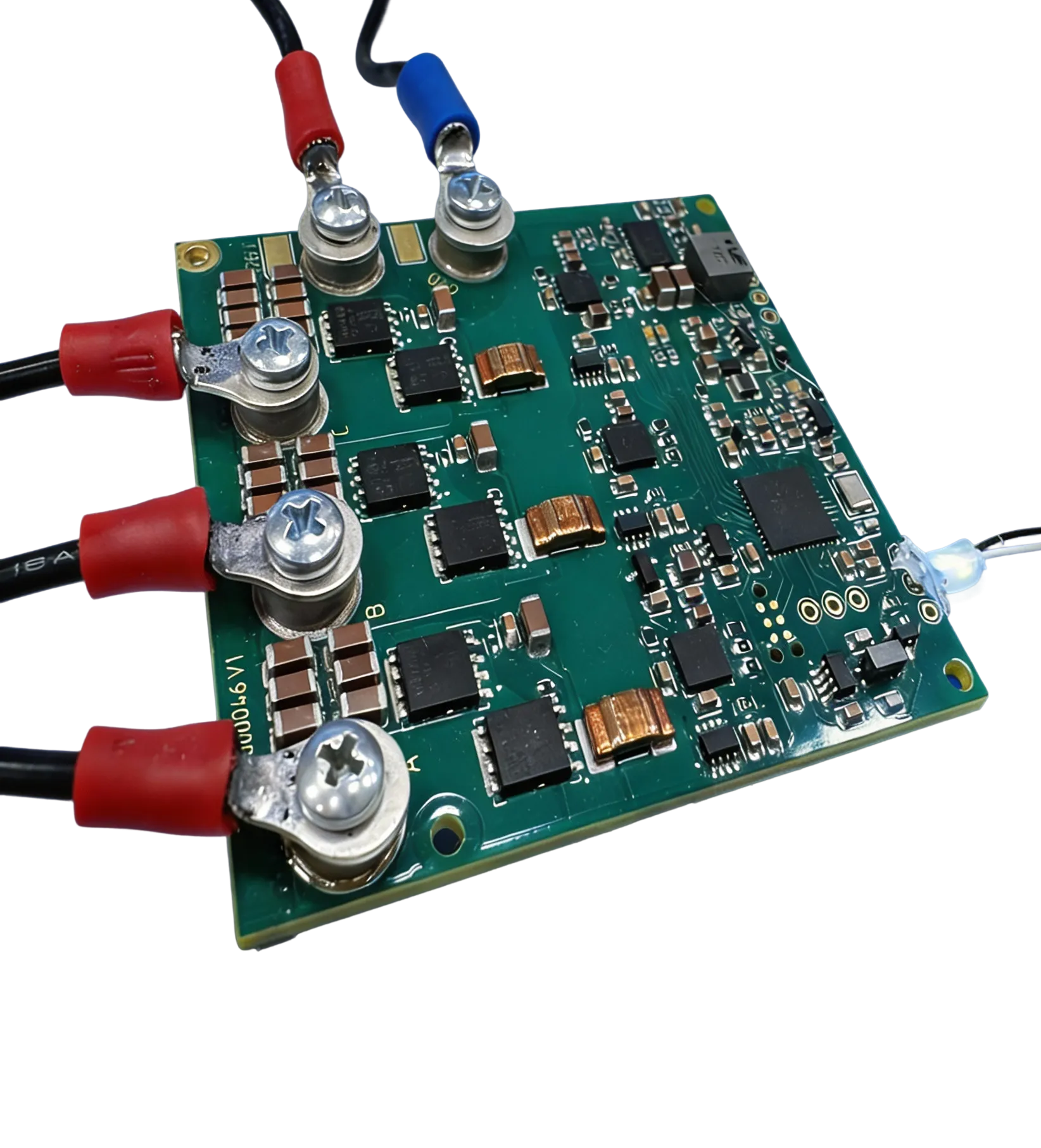

Firmware is tuned for sensorless zero-speed start and smooth transition to normal operation.

High breakaway torque required immediately at start

High start torque is needed for a short window

Where removing the position sensor improves reliability

Ready to simplify your motor system? Let's talk.